Manufacturing Capabilities

Our UK-based manufacturing facility is built around quality, traceability, and flexibility – with the capacity to handle everything from prototypes to volume production.

Whether you’re launching a new product or scaling an existing design, our in-house team delivers high-quality assemblies with complete control and transparency.

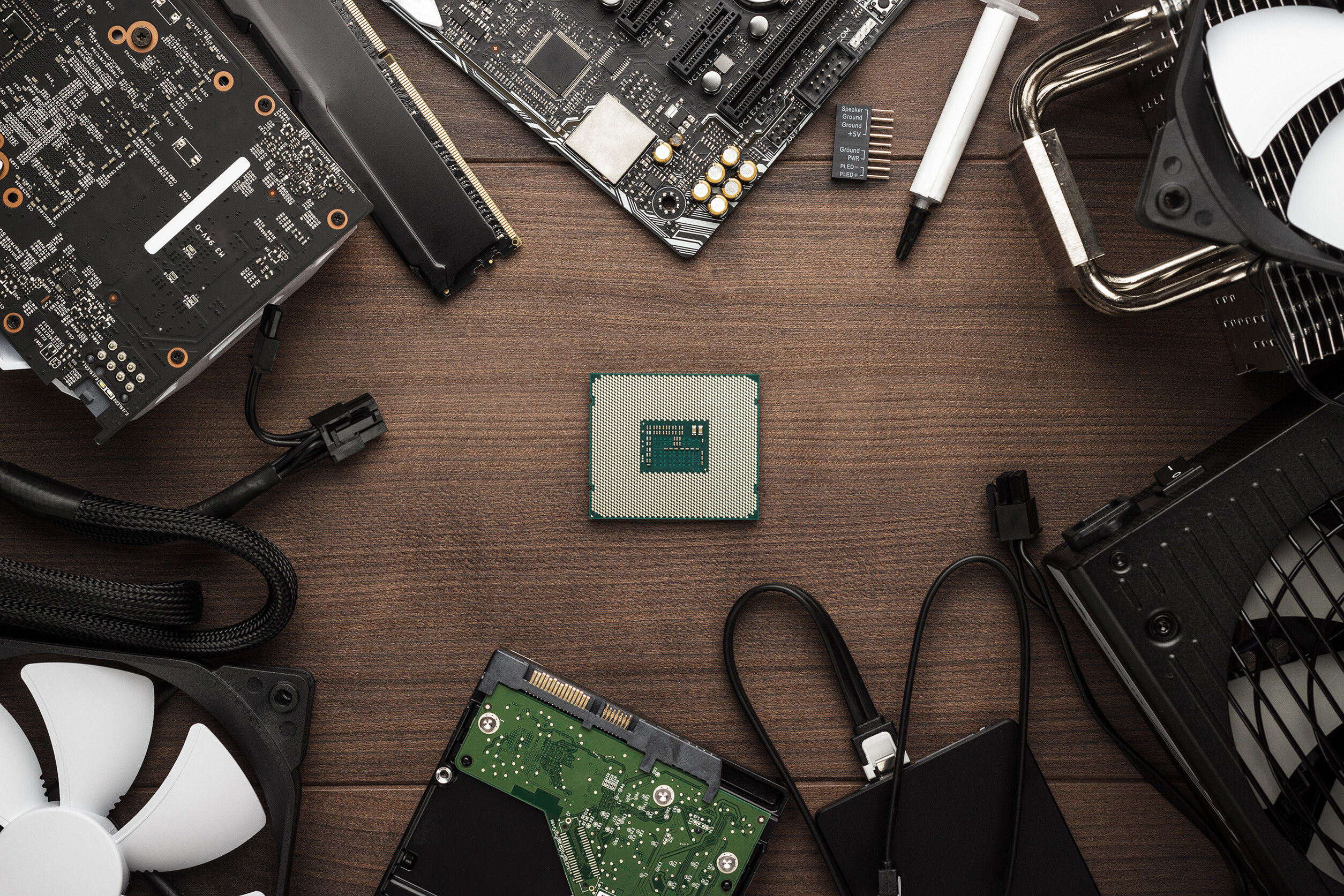

Our Core Manufacturing Elements

At BitBox, we combine technical expertise with robust processes to deliver high-quality, repeatable builds at scale. From component placement to final inspection, every stage is designed for precision, reliability, and traceability. Below are the six core elements that define our approach to manufacturing.

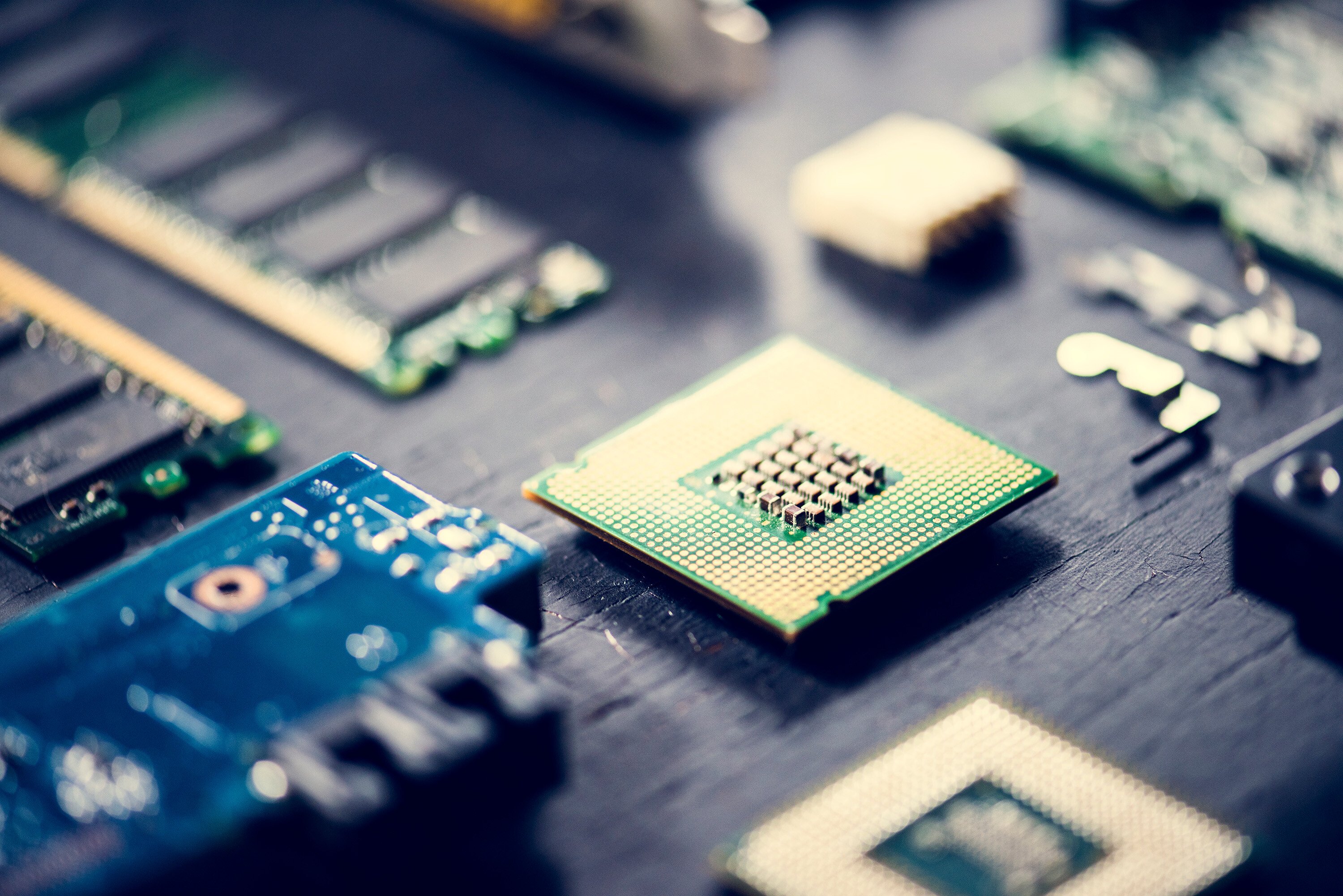

Surface Mount Technology (SMT)

High-speed, high-precision SMT with built-in component validation.

Automated Optical Inspection (AOI)

Final-stage 100% 3D AOI to verify all joints and components meet IPC standards.

Manual & Selective Soldering

Skilled hand through-holers and precision selective soldering with nitrogen ensure high-quality, repeatable joints.

Box Build, Assembly & Test

Complete product build and test - from sub assemblies to full enclosure integration.

Full Traceability

Barcode tracking and data logging provide complete production and component traceability from start to finish.

Additional Services

Conformal coating, PCB cleaning, BGA rework, and X-ray inspection available to support specialist requirements.

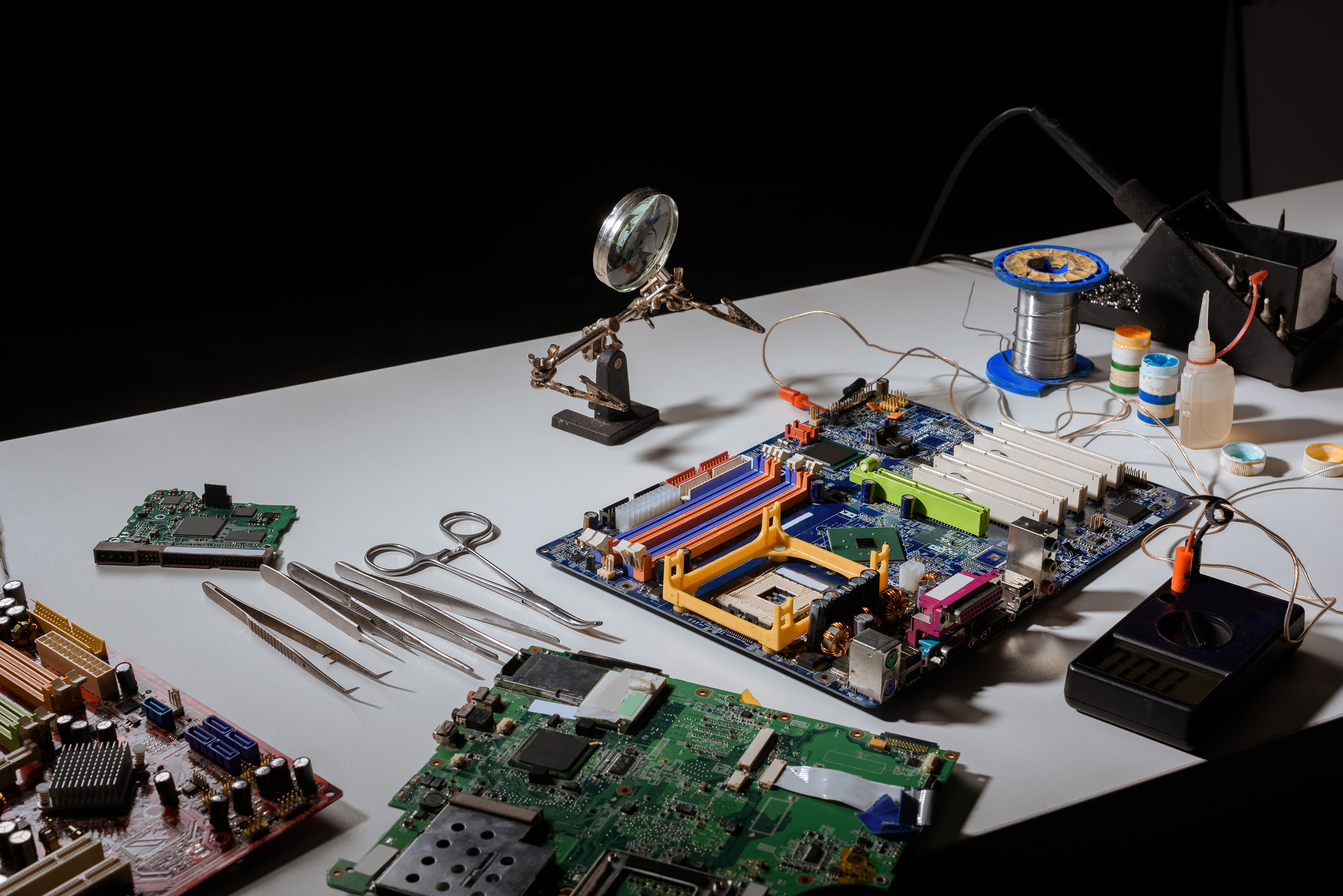

Surface Mount Technology (SMT)

We use high-speed Europlacer IINEO pick-and-place machines – known for flexibility and capable of placing over 48,000 components per hour, from tiny 01005 packages to large 50mm x 50mm devices (1,700 ball grid array). Our pick-and-place machines are loaded with smart feeders throughout and the machines themselves equipped with built in electrical test – enabling passive components to have first-off validation measurements prior to placement.

Automated Optical Inspection (AOI)

Our SMT line includes a SpeedPrint solder paste printer with 2D inspection and 100% 3D AOI (Automated Optical Inspection) at the end of the process to ensure every joint and component meets IPC standards. This 3D inspection system provides shadow-free height measurement and can measure solder volume at the joint – this gives us huge confidence in the product leaving the factory.

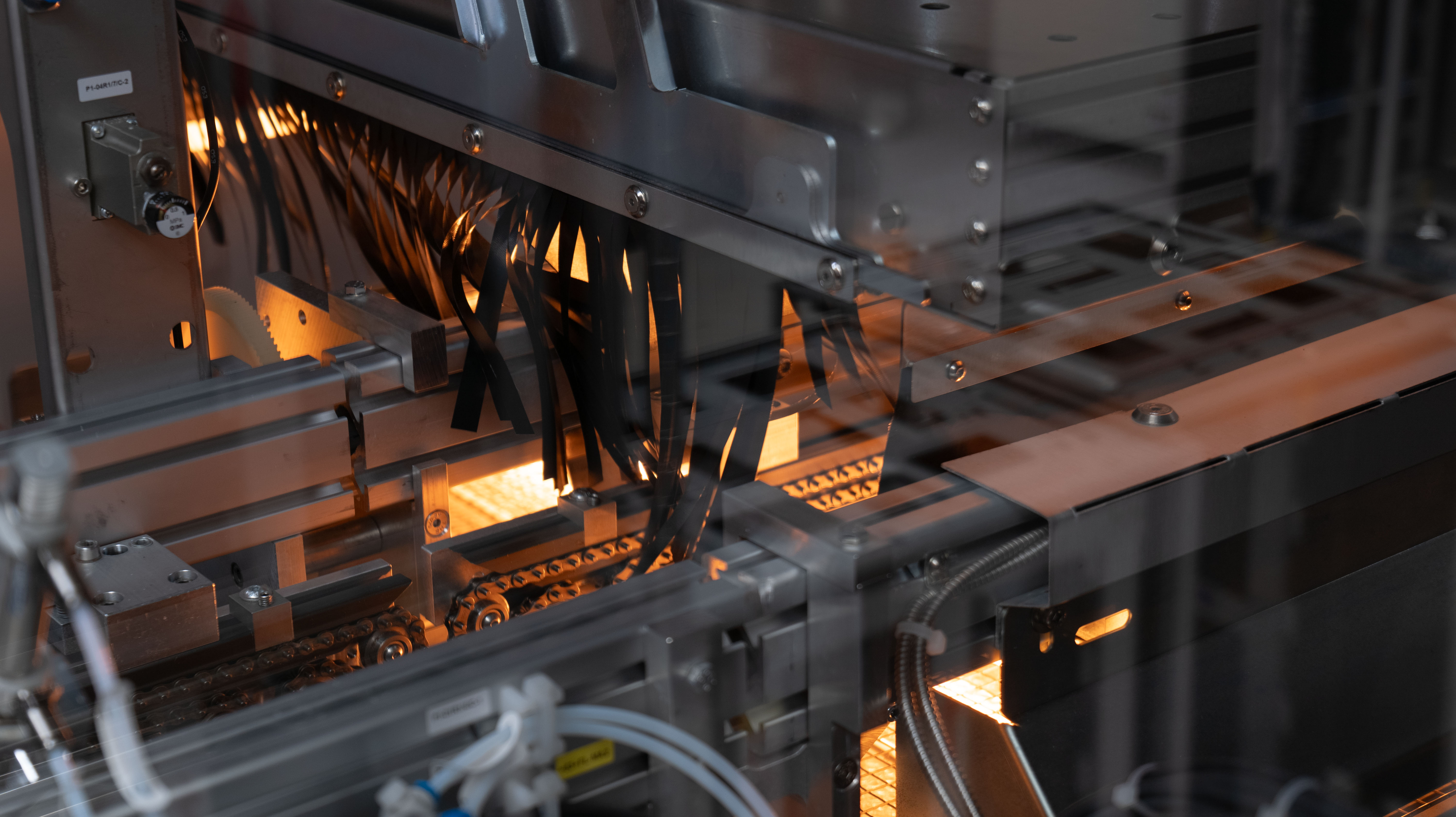

Manual & Selective Soldering

For rigid PCBA, we use ERSA VersaFlow One - selective soldering equipment to ensure repeatable and precise soldering.

A nitrogen supply is used throughout the process to improve joint quality and reduce oxidation – especially important when working with lead-free solder or sensitive components. Our team of highly skilled and experienced manual Through-hole personnel are on hand to assemble more complex assemblies alongside.

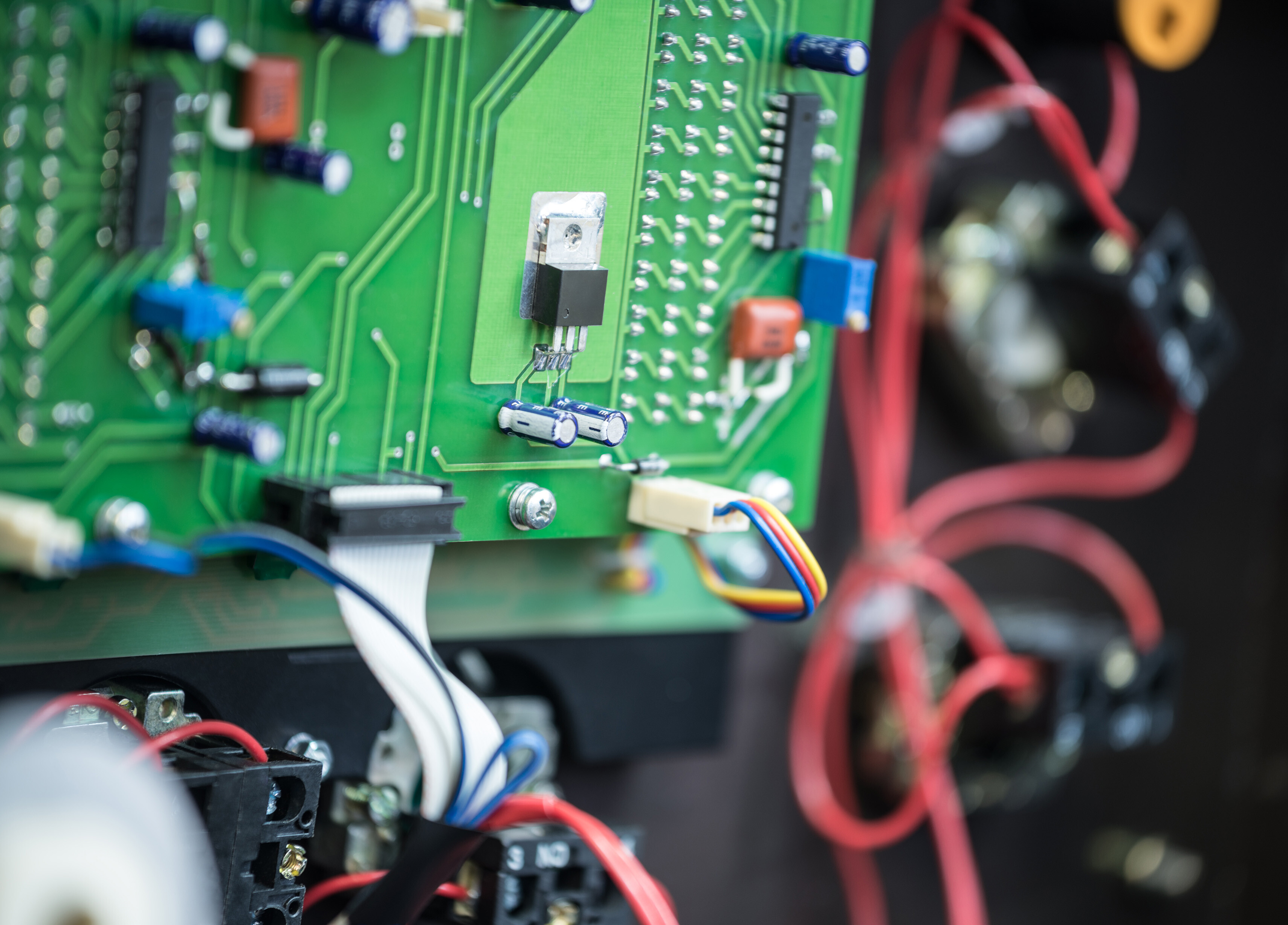

Box Build, Assembly & Test

Beyond the PCB, we offer complete product assembly. This includes sub-assemblies, wiring, chassis build, test, and full enclosure integration – all under one roof.

We work from your documentation or develop build instructions in-house, supporting everything from low-volume bespoke units to fully assembled, tested and packaged products.

Full Traceability

Our barcode-based tracking system records every step of the build – from SMT setup through to final test and assembly.

All manufacturing and test data is logged in a centralised database, giving you full traceability and production history for every unit we build.

Industries we support

Industrial Automation

No matter your sector, we deliver precision, reliability, and innovation at every stage.

Automotive

Driving performance and reliability with advanced manufacturing solutions tailored for the automotive industry.

Scientific Equipment

Empowering research and innovation with precision-engineered solutions for cutting-edge scientific applications.

Consumer Electronics

Creating high-quality, user-centric products to meet the demands of today’s tech-savvy consumers.

IoT & Smart Technology

Enabling intelligent connectivity with robust, scalable solutions for the connected world.

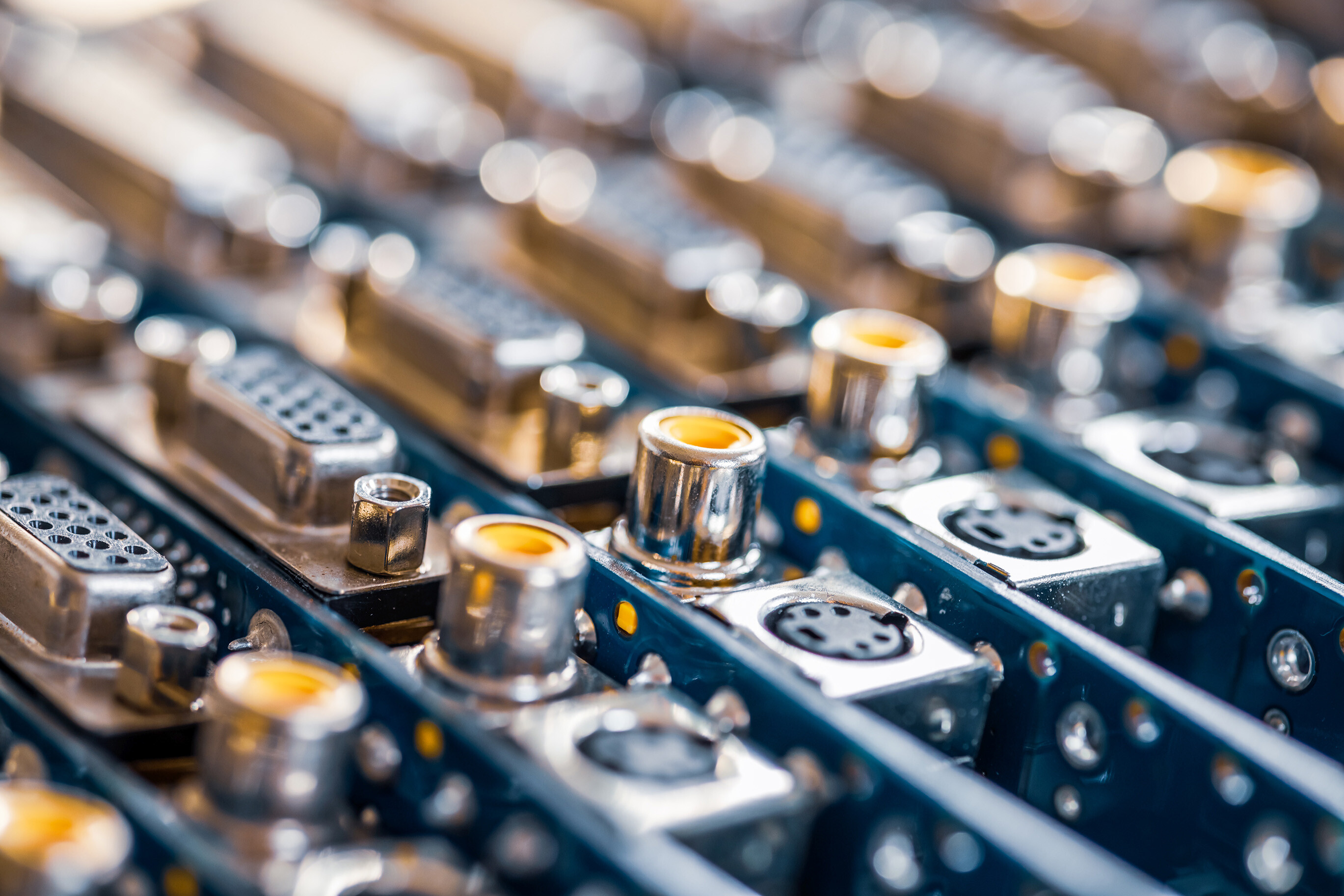

Communication Electronics

Facilitating seamless connectivity with reliable, high-performance communication technologies.

Let’s Build Something Exceptional

At BitBox, we’re not just your manufacturer—we’re your partner. From concept to production and beyond, we’re with you every step of the way, ensuring your product is the best it can be. Whether you need prototype development, scalable production, or long-term lifecycle management, we’re here to help.