A genuine partnership through production

At BitBox, manufacturing isn’t just about assembling electronics—it’s about creating something that works flawlessly, lasts longer, and delivers real value to you and your customers. We don’t just take your design and build it; we become part of your team, guiding you through every stage of the process to ensure the best possible outcome. Whether you need full end-to-end support or expert manufacturing services, we’re here to make sure your product is built right and built to last.

A seamless transition from design to manufacture

If you’ve worked with us on design, you already know our commitment to precision and quality. If you’re coming to us for manufacturing, you’ll quickly see that we treat your product with the same level of care as if we designed it ourselves. Our process is seamless, ensuring smooth transitions from prototype to full production, with expert oversight at every step. And when the time comes to scale, we’re ready to grow with you.

Full-service partnership

From initial design to manufacturing and lifecycle management.

Manufacturing-only support

Bring us your design, and we’ll build it to the highest standards.

Design expertise

If you’re still refining your concept, our design team is here to help.

More than manufacturing – a commitment to your product’s success

BitBox goes beyond traditional contract manufacturing. We take full accountability for the quality and performance of every product we build. We don’t just produce hardware; we actively refine and enhance it, ensuring long-term success for you and your customers. Our expertise allows us to anticipate potential challenges, mitigate risks, and implement solutions that keep your product performing at its best.

From early-stage prototypes to high-volume production, our support never stops. We believe in building lasting relationships, working as an extension of your team to ensure that your electronics are not only built right today but continue to deliver value long into the future.

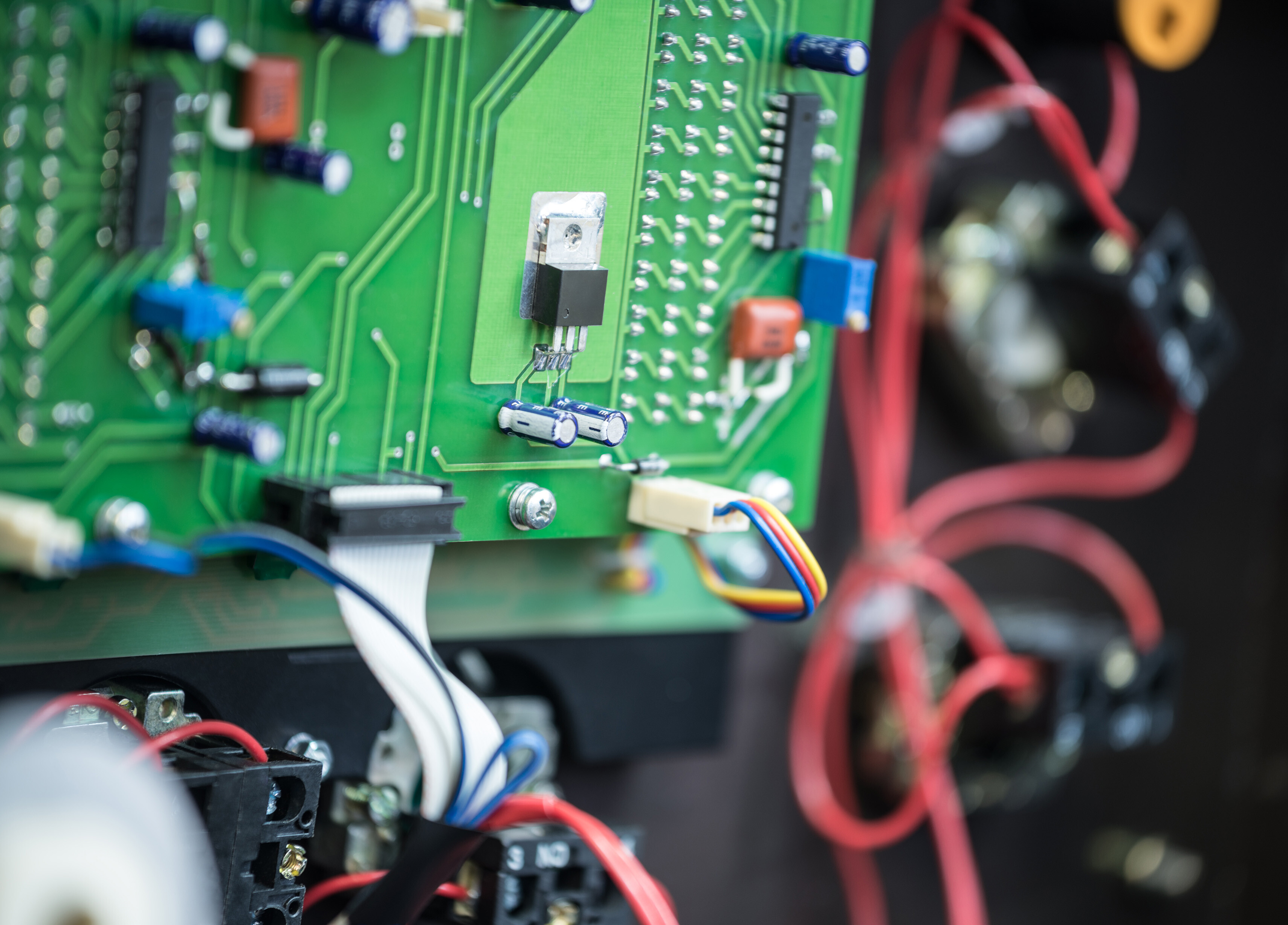

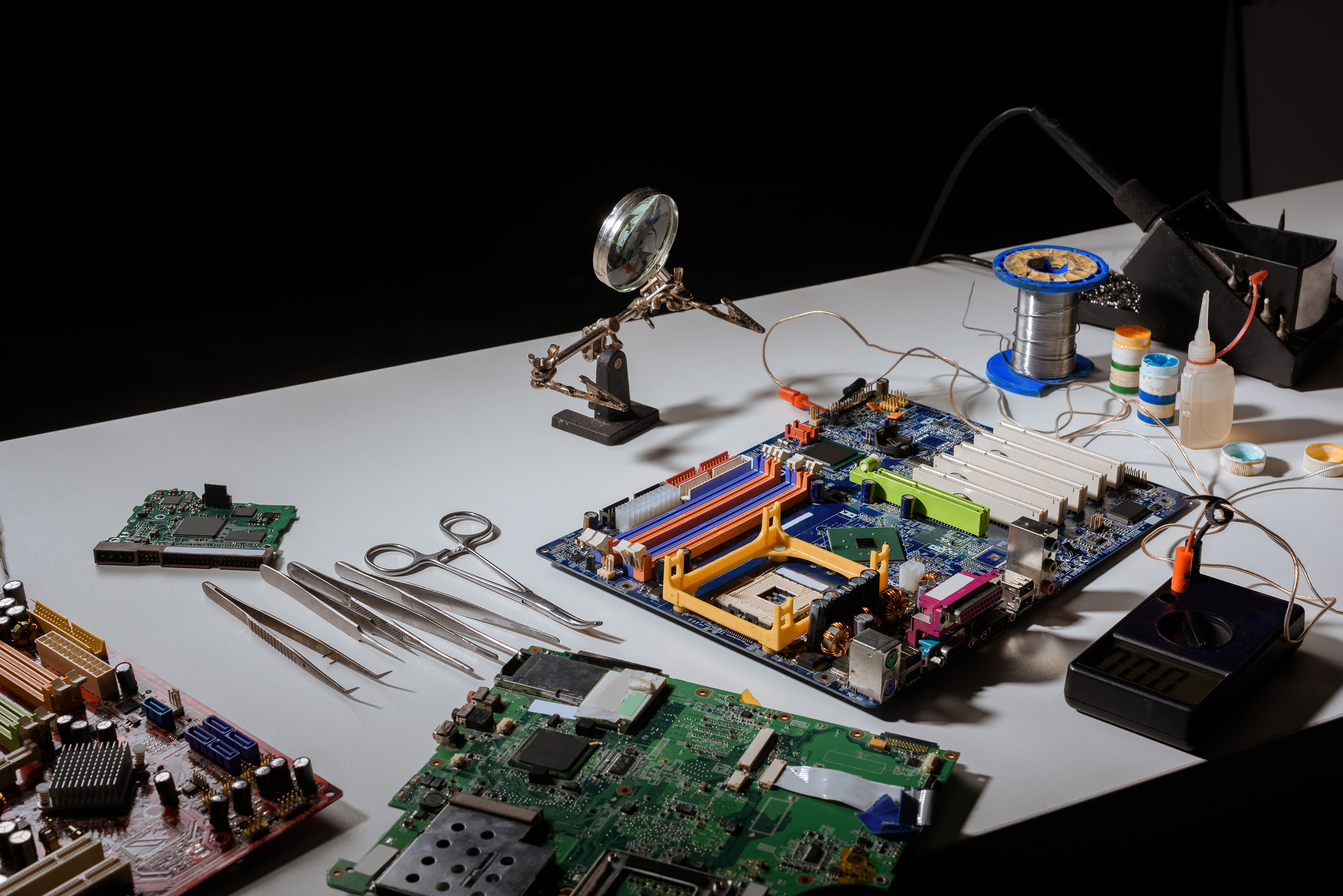

In-depth Design Verification

- Refinements to optimise performance and manufacturability

- Seamless transition to production

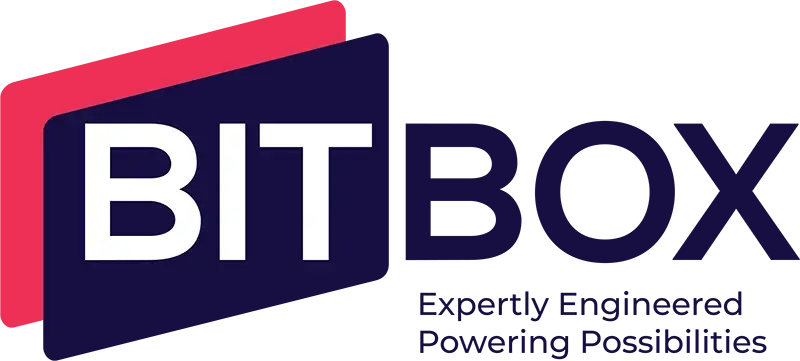

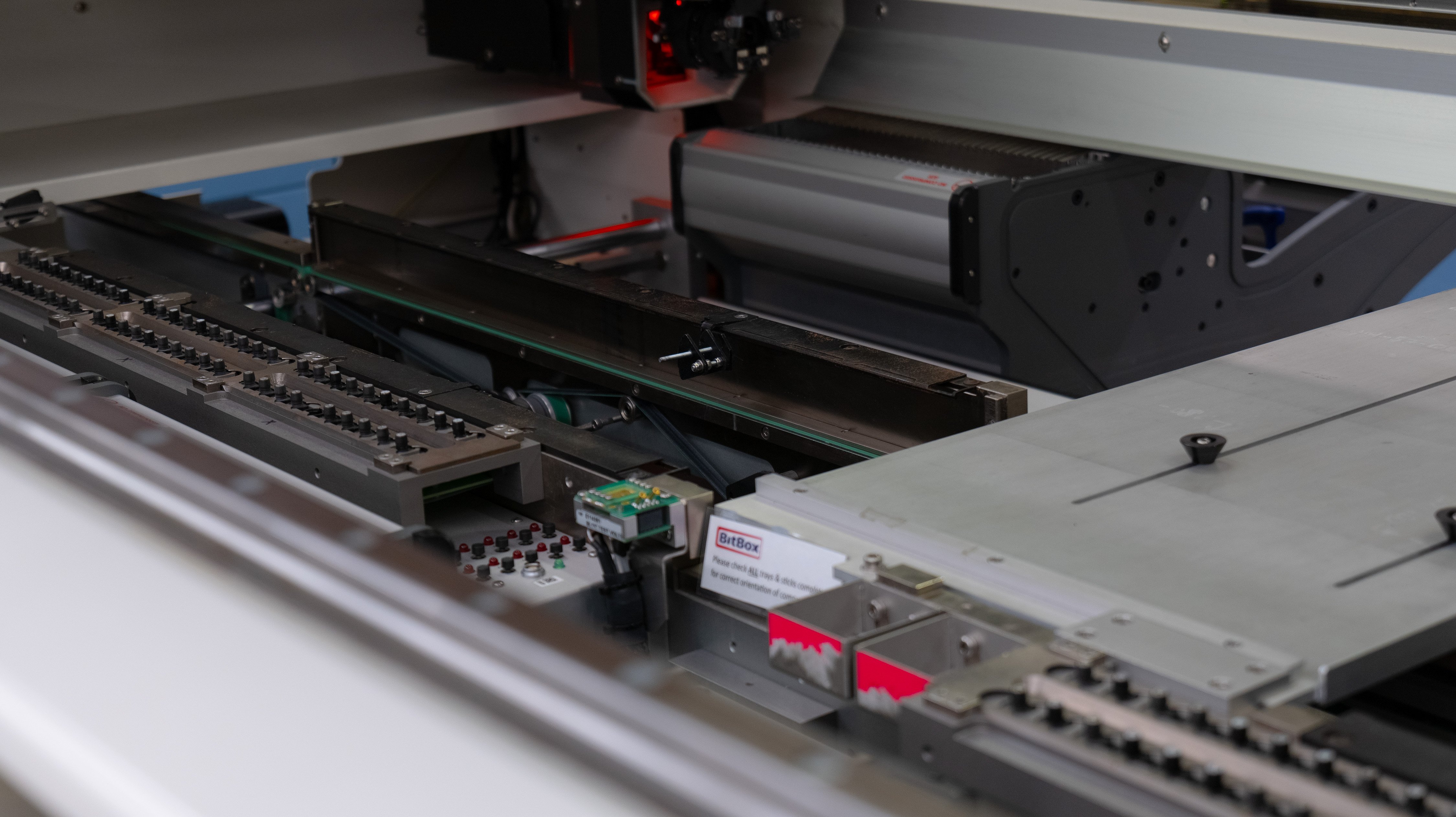

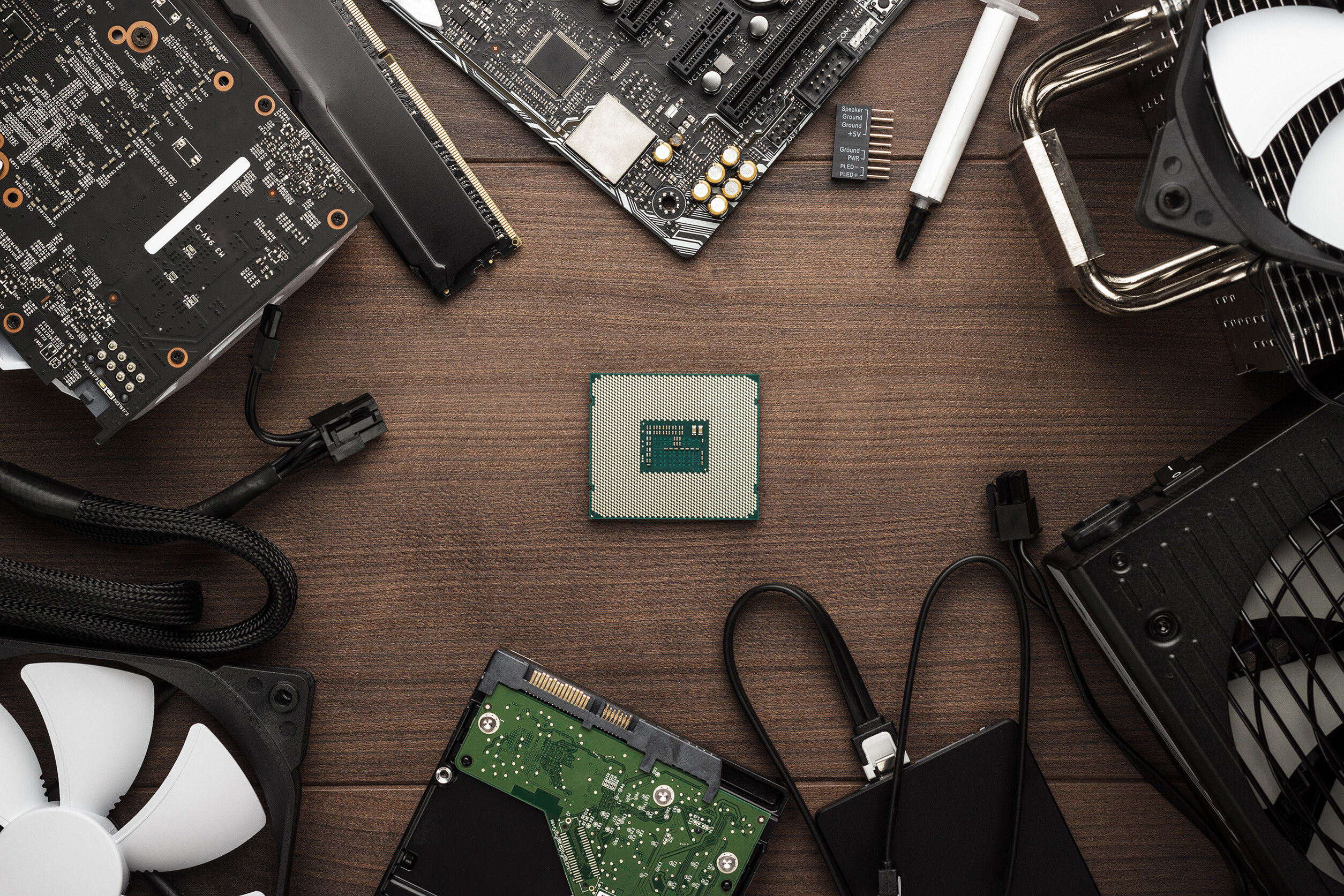

Scalable, High-Quality Production

- PCB assembly with precision engineering

- Robust quality control and testing protocols

- Flexible production volumes to suit your needs

Lifecycle Management & Ongoing Support

- Obsolescence management to future-proof your product

- Sustainability-driven approaches for long-term reliability

- Continuous improvements based on real-world performance

Why choose BitBox for manufacturing?

With in-house capabilities covering the full product lifecycle, our team in Basingstoke ensures a controlled, efficient, and high-quality manufacturing process from start to finish.

Commitment to Quality & Compliance

Every product we manufacture follows strict ISO-certified processes, ensuring safety, durability, and reliability in every batch.

UK-Based Production for Faster, Safer Delivery

By manufacturing in the UK, we offer shorter lead times, enhanced supply chain security, and stringent quality control—giving you complete peace of mind.

Scalable, Cost-Effective Solutions

Whether you’re at the early stages of development or ramping up to high-volume production, our flexible approach keeps costs optimised without compromising on performance.

Sustainable, Future-Proof Manufacturing

We prioritise responsible materials, efficient processes, and proactive obsolescence management, ensuring long-term sustainability for your product.

Design Expertise at the Heart of Manufacturing

At BitBox, we integrate our engineering team directly into the manufacturing process - delivering added value at every stage of your product’s journey.

Our highly skilled engineers work closely with the manufacturing team, offering real-time support, expert guidance, and on-site problem solving. This unique approach means smarter designs, faster resolutions, and more efficient builds - helping you reduce rework, cut costs, and optimise performance.

Whether it’s refining work instructions or advising on efficiency opportunities, our electronic engineering expertise is always within reach.

We’re your design and manufacturing partners - making sure every product is built right and built to last.

Industries we support

Industrial Automation

No matter your sector, we deliver precision, reliability, and innovation at every stage.

Automotive

Driving performance and reliability with advanced manufacturing solutions tailored for the automotive industry.

Scientific Equipment

Empowering research and innovation with precision-engineered solutions for cutting-edge scientific applications.

Consumer Electronics

Creating high-quality, user-centric products to meet the demands of today’s tech-savvy consumers.

IoT & Smart Technology

Enabling intelligent connectivity with robust, scalable solutions for the connected world.

Communication Electronics

Facilitating seamless connectivity with reliable, high-performance communication technologies.

Let’s Build Something Exceptional

At BitBox, we’re not just your manufacturer—we’re your partner. From concept to production and beyond, we’re with you every step of the way, ensuring your product is the best it can be. Whether you need prototype development, scalable production, or long-term lifecycle management, we’re here to help.